Product Description

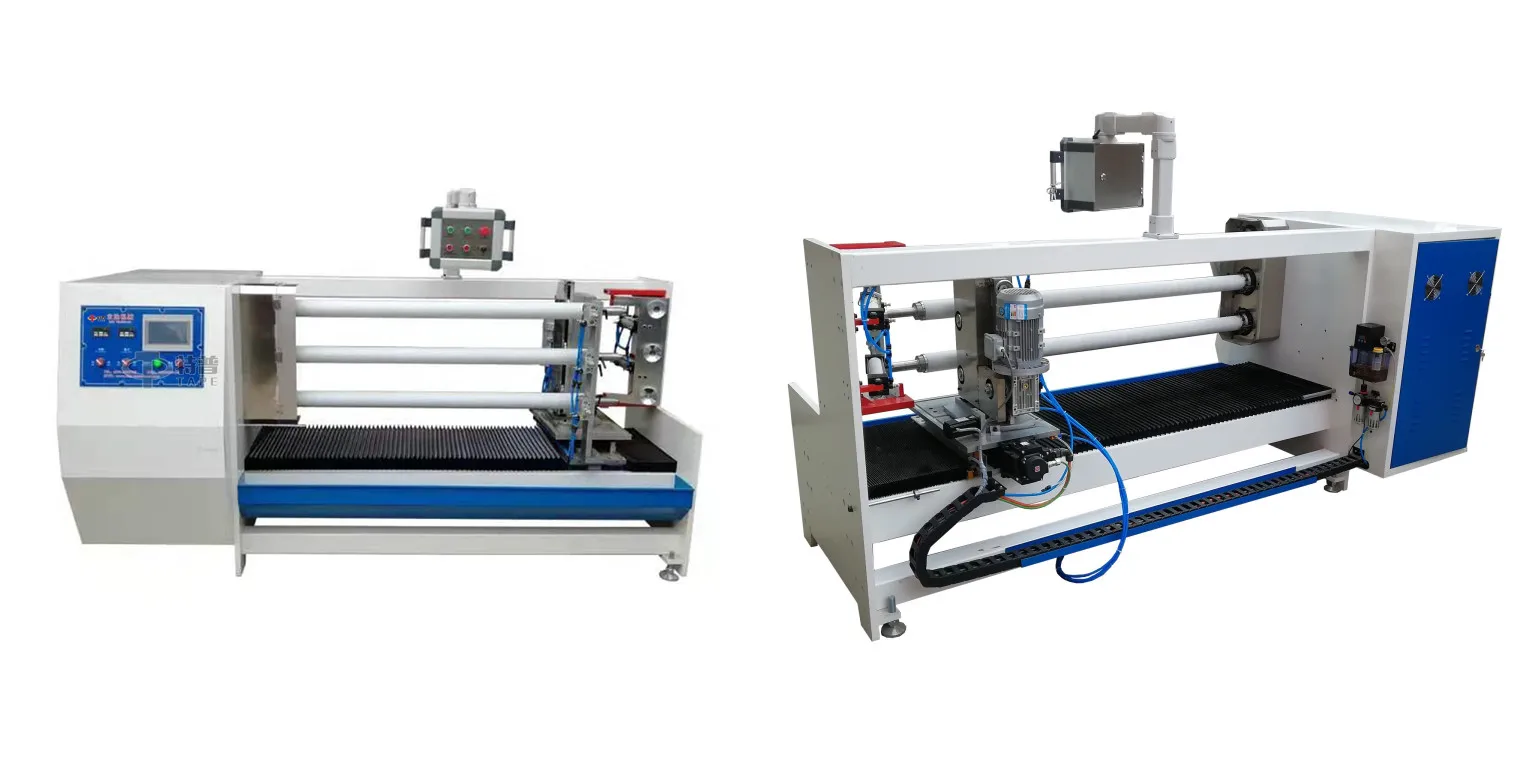

Four Shafts Automatic Adhesive Tape Jumbo Roll Cutting Machine

Feature of this BOPP jumbo roll slitting machine:

This machine is easily controlled by the panel; electronic counter control the length accurately; high efficiency; frequency;control;1300mm bopp slitter machine bopp cutting machine 500mm mini slitting machine small bopp

Technical parameter of Auto tape roll cutting machine:

1300mm 1600mm three shaft automatic adhesive tape masking tape foam tape slicing machine

|

Max.Winding Diameter

|

300mm

|

|

Max.Cutting Speed

|

35cuts/min

|

|

Max.Cutting Length

|

1300mm

|

|

Core Diameter

|

25.4-76.2mm

|

|

Cutting Width

|

3-1300mm

|

|

Motor Power

|

5HP

|

|

Drive Motor of Blade

|

3HP*6P

|

|

Diameter of Circular Blade

|

150-350mm

|

|

RPM of Blade

|

360-1800rpm

|

Feature: China Factory made BOPP tape cutting slitting machine

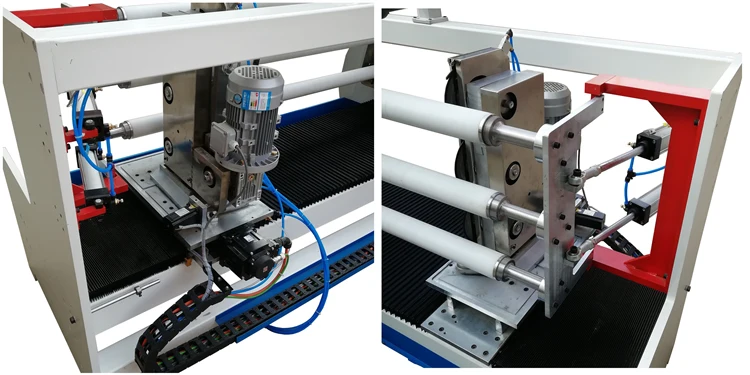

1. Automatic length setting: the two-step length counter provides accurate rewinding length control.Once the set length is

reached, servo motor is adopted so that shafts will instantly and automatically change, ensuring easy operation and efficient performance.

2. Programmable controller: the high performance programmable controller offers convenient control of the entire rewinding operation. Both length and tension are accurately displayed by LCD readout.

3.The paper core is held firmly on the pneumatic shaft. With easy, fast loading and unloading, it greatly improves efficiency.

4. Automatic smoothing device (optional): this wipe down device fully eliminates the problem of wrinkling and air bubbles in the product after rewindng. This device further ensures the smoothness of product.

5. Oil pressure material loading device (optional): this device offers easy material loading for operational convenience and improves efficiency.

6. The pressing roller is controlled by the cylinder and the pressure is adjustable. The semi-finished products are properly pressed to ensure smooth, stable running during rewinding.

Our Services

Why Choose us?

1. Product quality: Quality tesing records in manufacturing & expriments.

2. Price guarantee: Fine & brand quality materials,parts on machine.

3. Delivery guarantee: Related brochures along with delivery:

operation&maintenance;

installation drawing;

operation books for relater parts of outer supply;

spare parts list and stand accessories.

4. After sales guarantee: The seller is responsible for changing the parts which have the quality problem of the machines in one year,but except from the wearing parts and the quality problem were leaded by wrong operation and other man-made factors,and the quality problem should be confirmed by two sides.

Packaging & Shipping

Packing & Delivery of Adhesive Tape Slitting Machine

Packing & Delivery of bopp gum tape production line for carton sealing tape

Shipping: by express,by air,by sea

packing: carton box,wooden frame,wooden case,fly case

Shipping:by express,by air,by sea

packing:carton box,wooden frame,wooden case,fly case

Company Information

About US

Dongguan Tepu Automation Equipment Co., Ltd.We are the professional manufacturer for BOPP adhesive tape making machine, bopp tape slitting machine, Adhesive tape cutting machine, adhesive tape coating machine, slitting mahine , rewinding machine , packaging mahcine and so on.

We are a high-tech enterprise, which is professional in machinery design & manufacturing. We have a R&D team with experts, senior engineers and professors as key backbone.

We are making great efforts to develop new products to meet different requirements. Strict quality control was conducting in every procedure from material sourcing, processing and testing to packing, which guarant our products with reliable performance.

Our business got very fast expanding. We have had a good reputation among our customers because of our perfect services, quality products and competitive prices. We warmly welcome all customers cooperation with us.

FAQ

1. What is the ratio of raw material to produce BOPP packaging tape?

Normally, 1 ton BOPP film+1.7ton glue + Paper Core and we can get about 2 ton BOPP tape after drying.

2. What is the BOPP film and the coating thickness?

We suggest the 22 micron Bopp film and 28micron glue

3. What is the requirement of the glue?

Sloid content 54%+1, pressure sensitive acrylic adhensive

4. What is the production cost of the packaging tape in China?

About USD 0.085 per square meter

5. What is the consumption of the BOPP tape machine,such as electricity ,water, and others?

The 500mm tape machine consume about 10kg water each day,but the power consumption is not fixed.

6. The adhesive Bopp tape machine is manual or automatic?

The tape machine need a air compressor,so it is automatic pneumatic control.